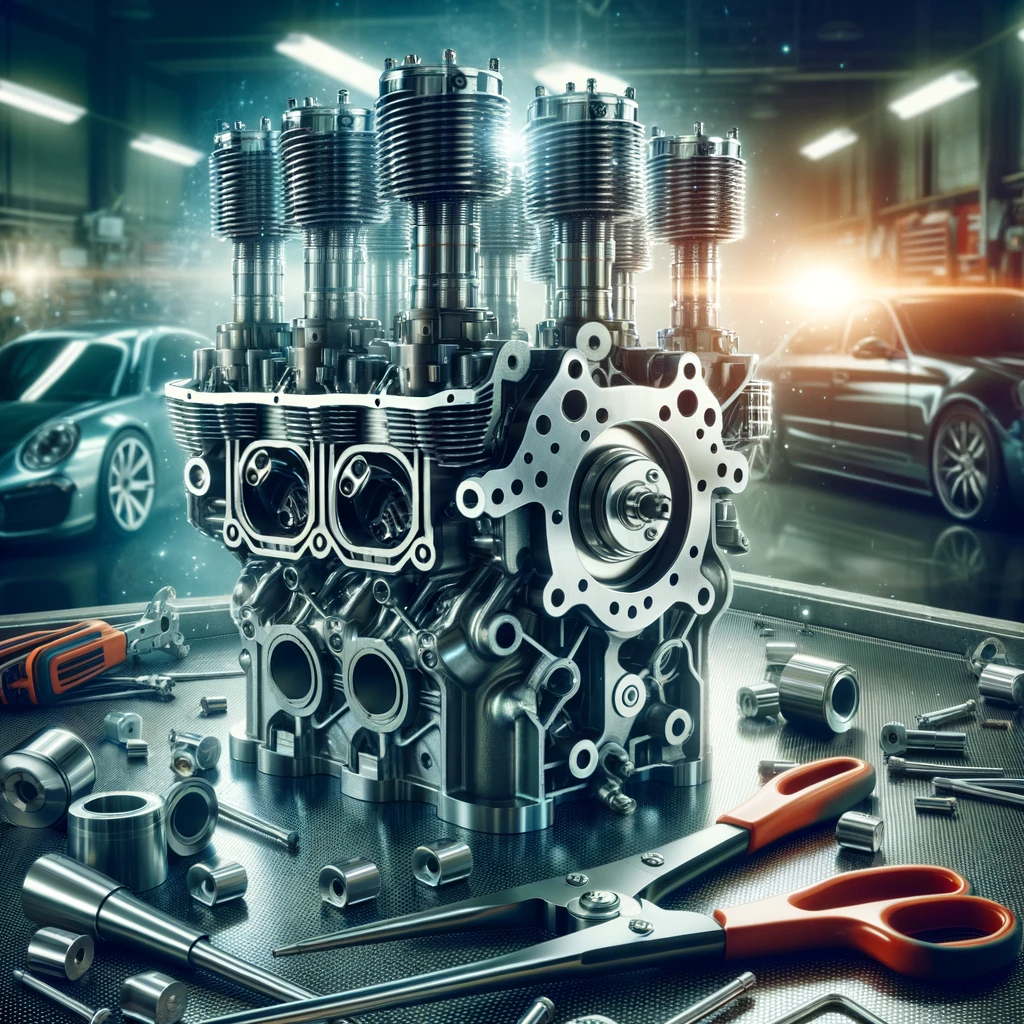

Learning about air cylinders installation is crucial for vehicle owners aiming to boost performance, especially in suspension and pneumatics. This process fits pneumatic cylinders into the vehicle, enabling precise functionality control, like adjustable suspension. Such enhancements significantly elevate the vehicle's aesthetics and handling.

Air cylinders play a vital role in automotive uses, offering unmatched adjustability and control. They improve ride comfort, allow ride height customization, and sometimes enhance handling. Ensuring correct installation is vital for the cylinders to work properly, enhancing performance while maintaining safety and reliability.

Understanding Air Cylinder Functionality

Before diving into the installation process, it's essential to understand how air cylinders work. These components use compressed air to exert force, which can translate into linear motion within the vehicle system. In automotive applications, this might mean adjusting the height of the vehicle’s suspension or actuating other components that require precise movement.

- Types of Air Cylinders: Familiarize yourself with the different types of air cylinders, such as single-acting (where air pressure is applied to drive the cylinder in one direction) and double-acting cylinders (where air pressure can be applied alternately for movement in both directions).

- Application Specifics: Consider the specific requirements of your vehicle and the intended application. The cylinder should be chosen based on the required force, stroke length, and the available space for installation.

Installation Process and Best Practices

Installing air cylinders is a detailed task that requires mechanical skill, precision, and a thorough understanding of your vehicle’s pneumatic system. Here are key steps and considerations in the installation process:

- Proper Mounting: Ensure that the air cylinder is mounted securely. The mounting should be stable enough to handle the force and motion of the cylinder without causing misalignment or undue stress on connected components.

- Air Supply and Routing: Establish a reliable air supply to the cylinder. This involves connecting the cylinder to an air compressor or reservoir, with careful consideration of the routing of air lines to avoid kinks, leaks, or any obstruction.

Maintenance and Troubleshooting

Post-installation, regular maintenance is essential to keep the air cylinders operating efficiently. Regular checks can help identify and rectify issues like air leaks, rod misalignment, or wear and tear of seals and bearings before they lead to system failure.

- Regular Inspection: Conduct periodic inspections to ensure all connections are tight and the cylinder is free of dirt and debris.

- Lubrication and Cleaning: Depending on the type of air cylinder, some may require occasional lubrication and cleaning to maintain smooth operation and prolong the life of the components.

Selecting High-Quality Air Cylinders for Installation

Choosing the right air cylinders for your vehicle is crucial for enhancing performance, ensuring durability, and maintaining safety. Here’s how to ensure you pick the best ones for your needs.

Understand Your Vehicle’s Requirements

The first step in selecting the right air cylinders is to thoroughly understand your vehicle's specific needs:

- Application Purpose: Identify what you need the air cylinders for – whether it’s for adjusting suspension height, improving ride quality, or other specialized functions.

- Load Capacity: Determine the weight the cylinders will need to support. This is crucial for maintaining performance and preventing premature failure.

Evaluate Cylinder Specifications

Different air cylinders come with various specifications that dictate their performance and suitability for certain applications:

- Stroke Length: This is the distance the piston can travel in the cylinder. Ensure the stroke length is adequate for the range of movement you need.

- Bore Size: The diameter of the cylinder directly affects its force output, with larger bores providing more lifting or moving power.

- Pressure Rating: Check the maximum operating pressure the cylinder can withstand, which should align with your system's pressure levels to avoid overloading.

Check Material and Build Quality

The construction material and build quality of the air cylinders can significantly impact their longevity and reliability:

- Material Durability: Look for cylinders made from robust materials like stainless steel or aluminum, which offer durability and corrosion resistance.

- Seals and Bearings: High-quality seals and bearings are crucial for preventing leaks and ensuring smooth operation, which translates to reliable performance and longer service life.

Compatibility with Your System

Ensure the air cylinders are compatible with the rest of your vehicle’s pneumatic system:

- Mounting Configuration: The cylinder should fit securely in the designated space, with compatible mounting points that align with your vehicle’s setup.

- Connection Types: Verify that the cylinder's ports and fittings match up with your existing air lines and connectors to ensure a leak-free installation.

Want to learn more about air systems? Check out our latest blog post: What Is Air Suspension Kit Replacement?

Brand Reputation and Warranty

Opting for air cylinders from reputable brands can offer peace of mind and assurance of quality:

- Reputable Manufacturers: Choose brands known for their quality and reliability in the pneumatic industry.

- Warranty Coverage: A solid warranty can be indicative of the manufacturer’s confidence in their product, offering protection against defects.

Read Reviews and Seek Recommendations

Gathering insights from other users can provide real-world feedback on the performance and durability of the air cylinders:

- Customer Reviews: Look for feedback from customers who have installed similar air cylinders in similar applications.

- Expert Opinions: Automotive professionals or enthusiasts can advise on the best air cylinders for specific uses or vehicles.

Choosing Air Cylinders

Selecting the right air cylinders involves understanding your vehicle’s needs, evaluating the cylinders' specifications, ensuring material quality, verifying system compatibility, considering brand reputation, and leveraging reviews.

Making a well-informed choice will help you achieve the desired outcome, ensuring your vehicle operates optimally and meets your performance expectations.

Check out our selection at Airbagit.com and get the best products on the market!

Join our social media communities on Facebook and Instagram for the best tips and deals in the industry!