Maintaining your air horn is essential for ensuring it functions correctly and remains a reliable safety feature. This comprehensive guide will delve into the various aspects of air horn maintenance, the importance of choosing the right products, and how to integrate air horns with air ride systems, particularly focusing on Ford vehicles and the products available on Airbagit.com.

Importance of Air Horn Maintenance

Air horns are critical for safety, especially in larger vehicles or noisy environments where a standard horn may not suffice. Regular maintenance ensures that the air horn is ready to use when you need it most, preventing potential failures that could compromise safety.

Regular Inspection and Cleaning

Inspect your air horn system regularly for any signs of wear, damage, or corrosion. Clean the trumpets with a soft brush and soapy water to remove any debris that could affect the sound quality. Ensure that the air compressor and air tank are securely mounted and free from leaks.

Testing and Electrical Checks

Test your air horn periodically to ensure it's working correctly. Listen for any changes in the sound that could indicate a problem. Additionally, check all electrical connections for security and corrosion, including wiring to the compressor, switches, and relays.

Air Compressor and Air Tank Maintenance

The air compressor should be checked for wear and securely mounted. The air tank should be drained periodically to remove condensation, which can cause rust and damage the internal components.

Quality of Materials in Air Horns

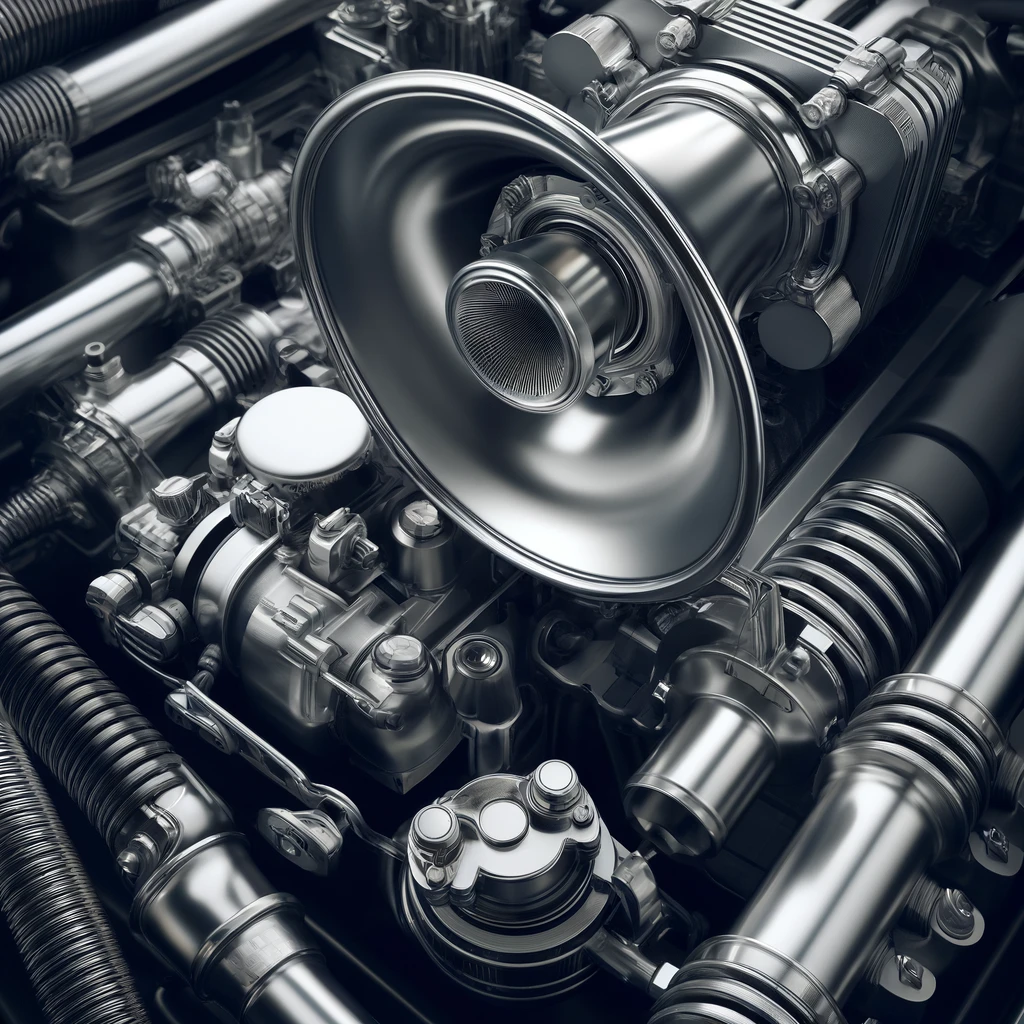

The quality of materials used in air horns greatly affects their durability, performance, and resistance to environmental factors. High-quality air horns are often made from materials such as chrome-plated zinc and ABS plastic, which provide excellent waterproofing, wear resistance, and corrosion resistance.

These materials help the air horn endure harsh weather and frequent use without losing quality or performance. For example, air horns made with chrome-plated zinc not only look better but also have a sturdy structure resistant to rust and corrosion.

ABS plastic is another popular material for its high impact resistance and durability, essential for parts exposed to the external environment.

When choosing an air horn, consider kits made from long-lasting materials like stainless steel or chrome-plated brass. These materials are known for their durability and ability to withstand various weather conditions and vibrations.

This ensures that the air horn remains functional over an extended period, providing reliability and reducing the need for frequent replacements.

DIY vs. Professional Maintenance of Air Horns

Deciding whether to undertake DIY maintenance or to seek professional help for your air horn involves considering several factors, including your technical skill level, the complexity of the maintenance required, and the potential risks involved.

DIY Maintenance

DIY maintenance of air horns can be a cost-effective option for those who have a basic understanding of vehicle electronics and access to the necessary tools. Simple tasks like checking connections, cleaning the horn, and basic troubleshooting can typically be performed by the vehicle owner.

This approach saves money on labor costs and provides a deeper understanding of the vehicle's operational aspects. However, DIY maintenance comes with risks.

Without proper knowledge and tools, there's a higher chance of incorrect installation or diagnosis, which could lead to further damage or ineffective operation of the air horn. Moreover, modern vehicles can have complex integrated systems that might be beyond the scope of typical DIY skills.

Professional Maintenance

It's advisable to seek professional maintenance for complex issues such as integrating the air horn with other vehicle systems or handling electrical faults that require specialized tools.

Professionals have the necessary skills, tools, and knowledge of the latest automotive technologies, ensuring accurate diagnostics and issue resolution without compromising vehicle functionality.

Professionals ensure maintenance adheres to safety standards and vehicle warranty requirements, providing reliability and peace of mind. This is crucial for ensuring the air horn functions effectively and safely, especially in critical performance emergencies.

Air Horns Maintenance Done Right

Maintaining your air horn promotes safety, not just compliance. Follow the provided tips to keep it ready for emergencies.

Check out our selection at Airbagit.com and get the best products on the market!

Join our social media communities on Facebook and Instagram for best tips and deals in the industry!